Busbars & Power Connections

Multilayer flexible equalizers

Application

Application

Intended for transmission of electric current between various electric installations, mechanisms, bus bars etc, when it is required to compensate the mechanical linear and temperature expansions, to balance the tensions and vibrations.

Used in

– transformers;

– generators, motors;

– switchgears;

– rectifiers;

– switching apparatus;

– electrodes;

– input leads to electrolyzers.

Design

Design

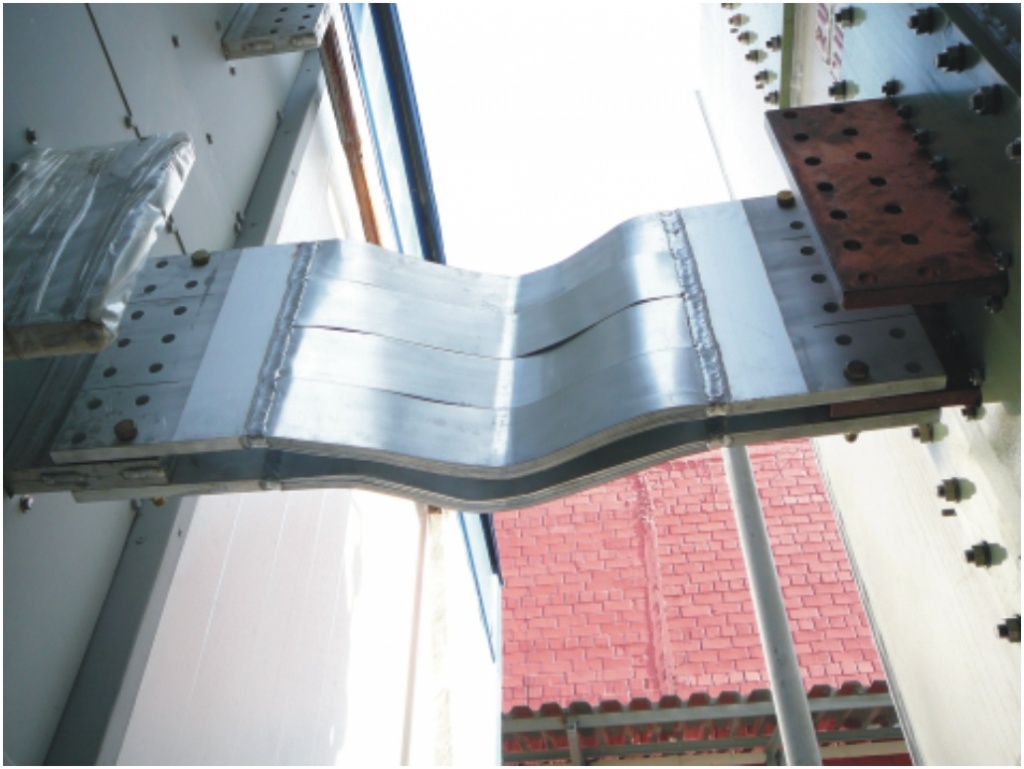

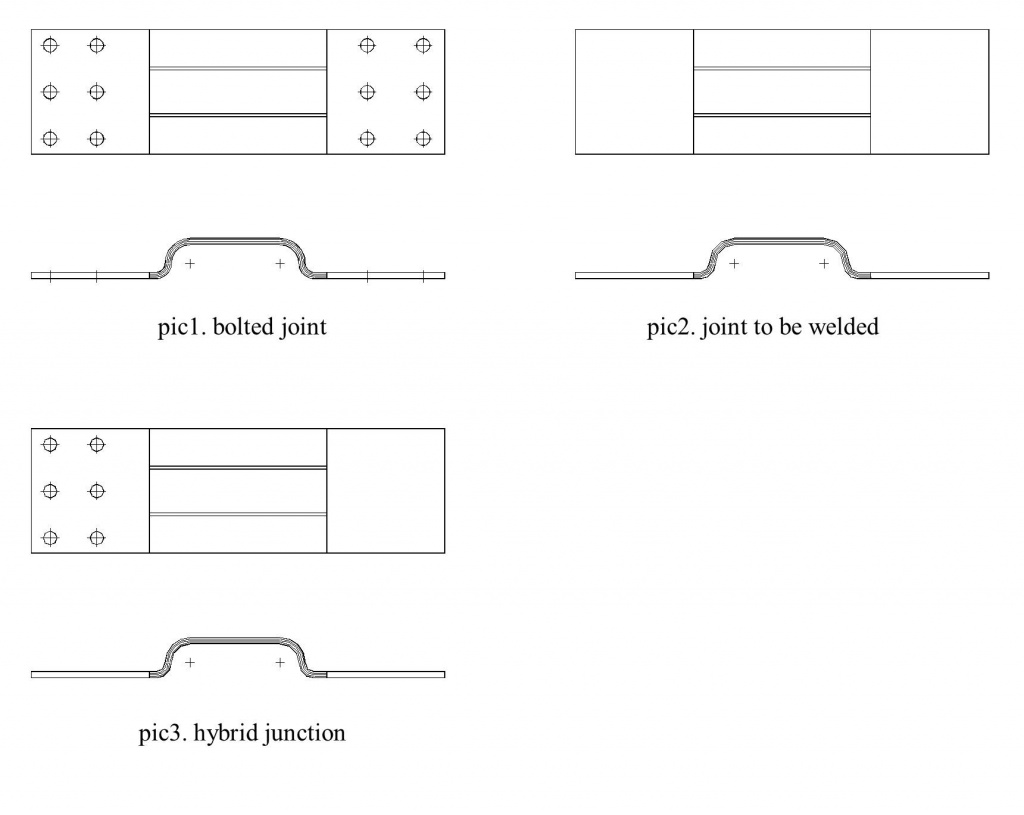

The construction is designed of two parts to be joined, with holes and without holes and of a flexible portion of a thin copper or aluminium strip in between those parts. The three parts are joined together by welding inside argon medium, or by pressure welding.

The parts to be joined are coated by nickel, which ensures steady – state copper – aluminium, or aluminium – aluminium contact.

Material

The equalizers are fabricated of copper or aluminium alloys. The flexible portion presents an assembly of thin plates (t = 0,5 ÷ 1mm), either straight or shaped. The parts to be joined are made of buses having standard dimensions (100, 200, 250mm), which enables to assure connection to the operating bus bars without changing the current loads to the joints. The bus equalizers are rated for currents up to 10kA. For greater currents use is made of parallel operation of compensators. The equalizers construction is designed and calculated individually for each Customer.

and calculated individually for each Customer.

The main criteria when choosing the design:

– current running through the equalizer;

– equalizer material;

– dimensions;

– requirements to flexibility;

– place of mounting;

– surrounding medium – aggressive or non – aggressive;

– ambient air temperature;

– kind of connection with the parts to be joined:

■ welding;

■ contact connection.

The equalizer material does not depend – as compared to other producers – on the material of the bus arrangement of the equipment to be joined, due to using innovation coatings by nickel, or by modified gallium.

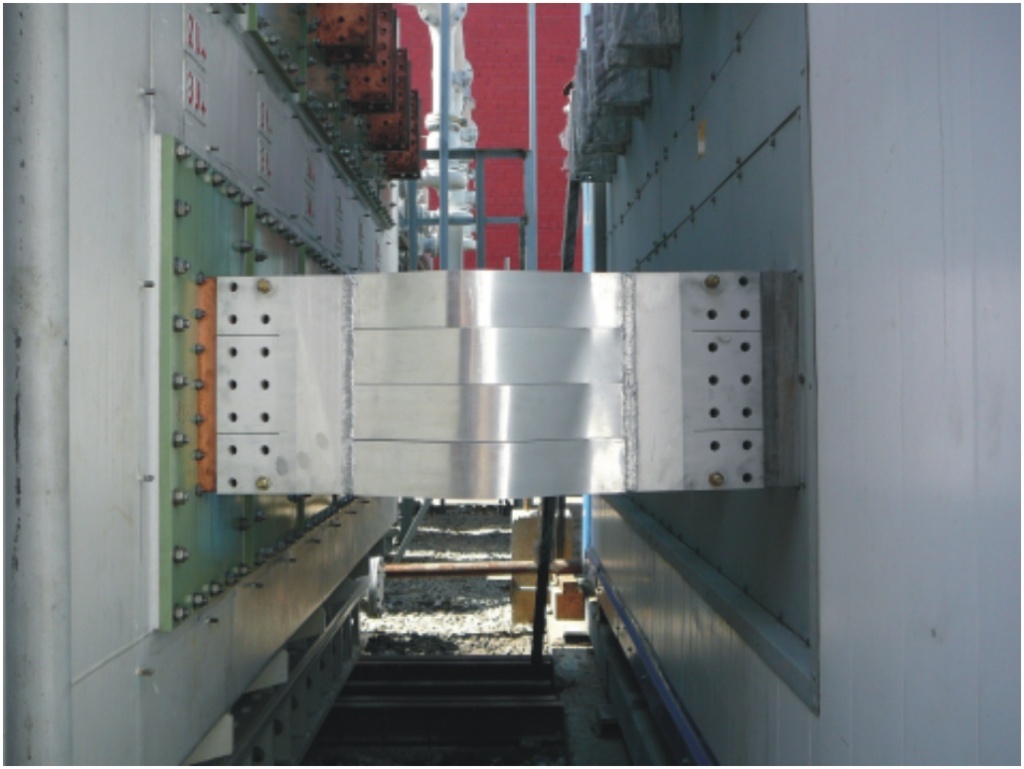

Example of bus equalizers

Welding process

Welding of the sheets is accomplished inside the inert gas medium, on the certified equipment of the welding bay by highly qualified welders.

Welding apparatus

Miller Syncrwave 350, 500, manufactured in USA – Canada.

Metals, which can be welded:

– copper;

– aluminium;

– steel;

Semi – automatic welding machine PHOENIX 521 Basic PULSforce Arc DW

Aluminium welding

Coatings

Depending on each particular case the places of particular connections may be coated by the following kinds of coating:

– nickel;

– copper.

Назад в раздел