Cooling & Heat Systems

Heat exchanging units with double loop "water-water"

Application

Application

Heat exchanging units are designed for cooling the semi – conductor converters and current conducting components of electric installations by deionized distilled water.

Design

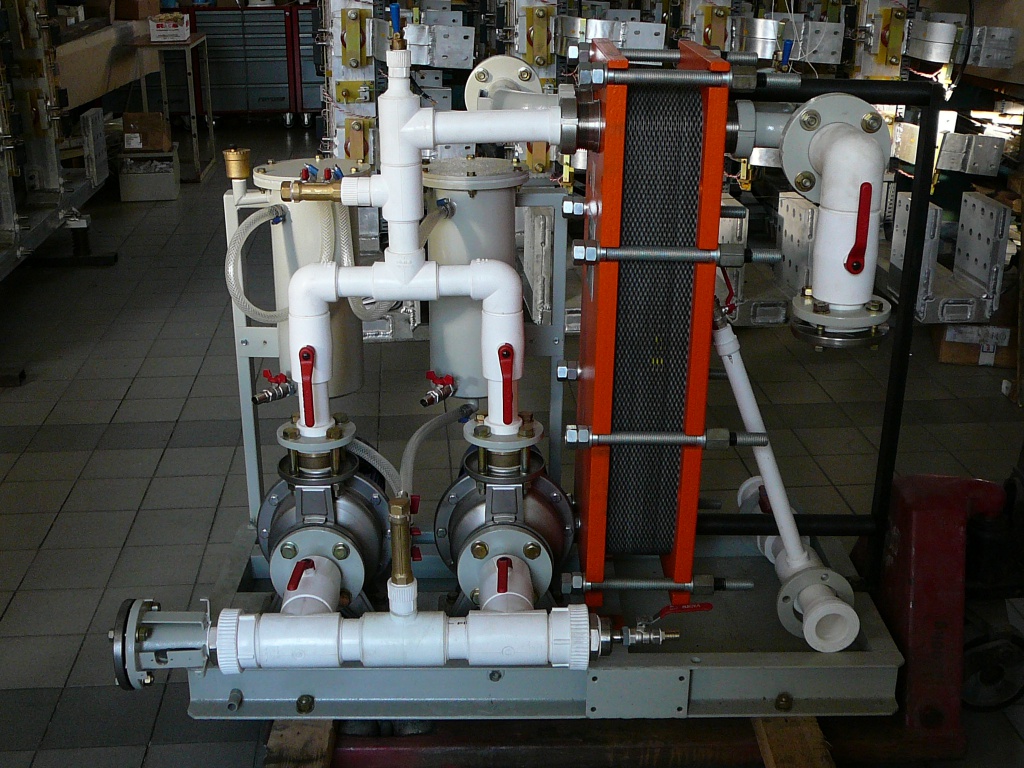

Heat exchangers incorporate the following main components:

- bearing frame;

- plate – type heat exchanger;

- circulating pumps – main and stand – by;

- stop pipeline valves;

- instrumentation;

- ion exchanging filter.

The plate type heat exchanger is actually a set of plates placed between the bearing and the pressure plates. The non – ferrous steel plates with projections form separate channels for two mediums, which participate in the process of heat exchange and move in counter – current flow. The inner loop – distilled deionized water, the outer loop – industrial water. Control and measurement of water temperature in both of the loops is assured by multi – channel digital meter. The system of monitoring and control ensures automatic changing – over to the stand – by pump, measuring temperature of the cooling water in as many as eight channels with information brought out by way of the built – in line adapter, forming the emergency opening signal in case of temperature rise above the set value in any of the channels.

Main specification

| Parameter name | Unit type | |||||

|---|---|---|---|---|---|---|

| HE–w/w–50 | HE–w/w–75 | HE–w/w–150

| ||||

| Output of removed heat losses, kW | 50 | 75 | 150

| |||

| Rated deionized water flow, m3/hr | 6 | 12,5 | 25 | |||

| Rated industrial water flow, m3/hr | 8* | 10* | 16* | |||

| Power rating of circulating pump motor, kW | 2,2 | 2,2 | 5,5 | |||

| Surface area to be cooled, m2 | 3,4 | 5,1 | 10,2 | |||

| Mass, kg | 390 | 430 | 550 | |||

| Overall dimensions, mm | 1300×600×1400 | 1500×800×1400 | 1650×800×1400 | |||

*defined by industrial water parameters.

Назад в раздел